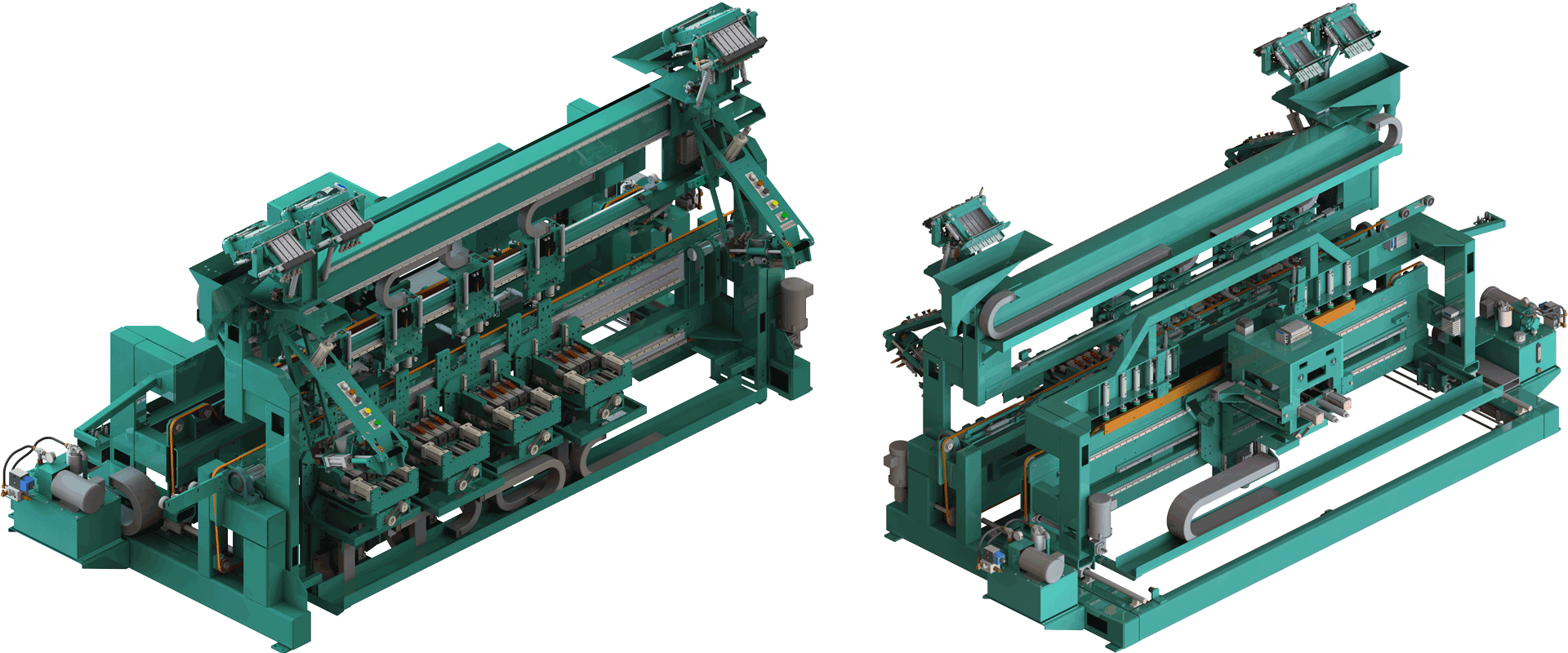

The New Standard in Speed & Flexibility

The 990-APEX redefines door and jamb machining flexibility by bridging the interior, exterior, and architectural/commercial markets. Designed with 75 years of experience and proven concepts at the foundation of our legendary 990 series, the APEX easily outperforms the competition.

Leveraging our patented KvalCAM® software—integrated with CNC technology—the 990-APEX provides complete control of all machine movement and precision cutting. It is the perfect machine for those looking to serve several markets with a single high-performance solution.

Key Features

The 990-APEX's standard configuration is capable of producing an incredibly broad range of products.

We also support custom configuration options if you need even more specialized flexibility.

-

Hinges

- Four independent CNC heads easily route for 3" to 4 ½" hinges, allowing you to specify location, depth, radius, and pre-drill patterns from the control panel for both the door and jamb. Use of clockwise and counter-clockwise high-frequency spindles eliminate material chip-out without the need for chip-out blocks. A third spindle is designated for point-to-point pre-drilling any hole pattern. Automatic corner squaring and concealed hinge capability are standard.

-

Lock Section

-

Routers mounted on the CNC tower in the lock section can machine the entire lock edge, making it possible to complete preps for three-point locks, deep mortise locks, flush bolts, and more. Face work in the lock section is completed with vertical spindles mounted on the same CNC tower, making function holes, different size bores, and irregular shapes all possible.

Corner squaring and point-to-point pre-drilling in the lock section are standard with the 990-APEX, and optional CNC ball-catch routers can be added to both bore and route for face plates on the door top.

-

Jambs

- The 990-APEX can machine and attach 3 ½" or 4" hinges with Kval’s original patented 6-Shooter and 8-Shooter technology for pre-hanging interior and exterior doors. KvalCAM allows the door and jamb to be machined separately to accommodate special hinges and strikes, such as ASA strikes and three-point lock strike jambs.

Cutting Edge Technology

The 990-APEX is equipped with the highest quality components.

Hi-Frequency CNC Controlled Routers

Increase hinge pocket quality with zero-compromise accuracy and durability.

Counter-Rotating Routers

Eliminate chip-out without chip-out blocks, changing hinge sizes is fast and done from the controller.

Point-to-point Pre-drill Spindles

Replace the air operated "gang drills" allowing for virtually any pre-drill pattern.

Selectable Chisels

Get consistently perfectly square hinges or face plates automatically.

High Quality Beckhoff Control Components

We've partnered with Beckhoff to equip the 990-APEX with cutting edge tech.

Laser Encoder

Enables real-time door thickness measurements and program adjustments for the correct hardware.

CNC Ball-catch Motors

For varying size, location, face plates, pivots, and flush bolt top/bottom plates.

Variable Run Modes

Prehanging, door-only, and/or jamb-only are fully supported.

Jamb Programming

Fully supports hinges and strike jambs (including three-point locks).

Specifications

Door

- Width

- 12" – 48"

- Length

- 78" – 96"

- Thickness

- 1 ⅜" – 1 ¾"

- Bevel

- 0° or 3°

Jamb

- Width

- 3 ½" – 8 ⅝"

- Thickness

- ⅜" – 1 ¼"

Hinge

- Routing

- 3" – 4 ½"

- Application

- 3 ½" & 4"

- Radii

- ¼", ⅝", & Square

- Maximum Depth

- 1"

- Distance From Door Top/Bottom

- 4" – 8 ¼"

- Centers

- 24" – 32"

Locks

- Supported Features

- Cylindrical, Mortise Pockets, Multi-Point, Flush Bolts*

- Face Detailing From Door Top

- 32" – 64"

- Face Detailing From Stile

- 1 ⅛" – 4 ½" (without routing into Ryertex®)

The Ultimate Software Platform

The 990-APEX is programmed and controlled by our patented KvalCAM® software that has been in development for over five years. Door files are easily created at the controller, offline, or automatically from your data system through its easy-to-use API.

No G-Code experience is necessary to program new and unique door files. Jobs can be queued for operator or automatic bar-code reader selection, and 3D drawings can be viewed in real time as the door file is created. All machine control, calibration, and tool management is done through KvalCAM’s intuitive UI.