We developed the KvalCAM software platform to take our industry leading CNC door equipment to the next level: it makes programming hardware templates and managing door jobs a breeze, giving you total control over tooling selection and hardware calibration, and much more!

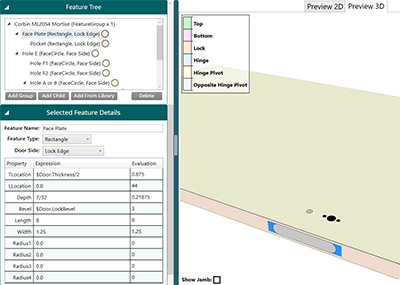

Easy & Intuitive Template Creation

KvalCAM allows you to easily create any hardware template without knowledge of G-Code: simply define the shapes, sizes, and locations of required machining and let the software do the rest. Complicated hardware templates such as Mortise Locks, Exit Devices, Edge Guards, Flush Bolts, Hidden or Olive Hinges, and Overhead Closers are easy to create and modify.

Door data such as bevel, thickness, swing, and other attributes allow a single lock template to be used on any door size, swing, or bevel configuration.

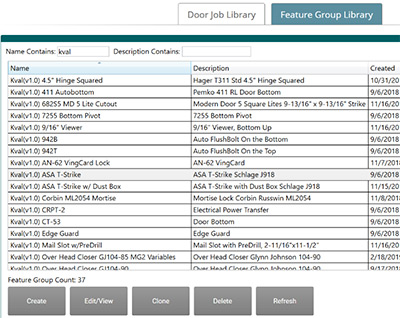

You can use fractions, decimals, equations, and even create variables in your templates, greatly simplifying the creation and editing process and reducing mistakes in interpreting hardware manufacturing templates. KvalCAM can automatically center face plates, pockets, and bore holes on equipment with the thickness measurement option. Locks, lights, and hinges are always measured to the top of the door for both right-hand and left-hand doors. KvalCAM comes preloaded with sample templates–or "feature groups"–of all types of commercial and architectural hardware.

KvalCAM can automatically center face plates, pockets, and bore holes on equipment with the thickness measurement option. Locks, lights, and hinges are always measured to the top of the door for both right-hand and left-hand doors. KvalCAM comes preloaded with sample templates—or "feature groups"—of all types of commercial and architectural hardware.

Looking for the KvalCAM documentation?

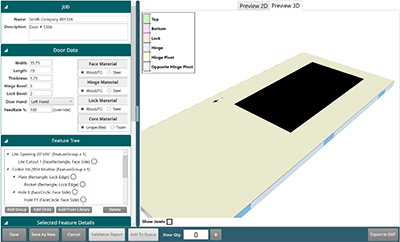

Simple & Powerful Door Job Management

Creating and queuing door jobs could not be easier with KvalCAM: simply define the width, length, thickness, bevel, and swing of the door then add hardware templates from your feature group library. Doors can be setup with hinges, locks, light cutouts, etc., then saved to the door library for future use in no time at all.

The template and door creation process can be done offline—or even off-site—to maximize equipment uptime and efficiency. Many of our customers utilize the built-in REST API to auto-generate door files using data from their order entry system, for example.

Fully Integrated

KvalCAM links multiple machines together, optimizing and controlling the operations of each machine. The Face SS, Edge SS, DL-NCX, and Vision Feeder/Stacker are combined into the Vision Line for a high-capacity architectural solution. The EFX can be combined with the DL-NCD for a low cost, yet complete, architectural manufacturing solution.

All of your machinery is unified by KvalCAM's robust backend database; having a single source of data frees you to develop your products without wasting time duplicating work. You can connect as many compatible machines to KvalCAM as needed across any number of plants.

Tooling & Calibration

You are in full control of the machine's tool selection, and calibration is straightforward and quick via the KvalCAM interface. Our machines come with standard tools but you can change the type, length, diameter, and even machining parameters of each tool available.

KvalCAM generates the machining code when the door job is entered using the tools available on the machine—you can swap out tools and the same door file will produce the exact same machined door. KvalCAM even has a tool path preview so you can see what tools will be used, the order of operation, and the exact path the motors will follow.

Machine Compatibility

Right now KvalCAM is compatible with the following machines, but as we further develop its capabilities this list will grow.

- 990-APEX

- All-in-one Architectural, Prehung, and Exterior door machine.

- 965X

- CNC Frame & Jamb Machine

- MLX

- Multi-Point Lock Routing System

- EFX

- For The Architectural Door Distributor

- Face SS

- Advanced CNC Function Router

- Edge SS

- Advanced CNC Door Processor

- DL-NCD

- Residential CNC Door Light Cutter

- DL-NCX

- Heavy Duty CNC Door Light Cutter

- Endeavor

- Versatile Edge & Face System

- Commander 3

- Interior, Exterior, & Commercial Edge & Jamb Router

- Vision

- Powerful Feeder/Stacker

- Door Transport System

- The "Do Everything" Conveyor Platform

Training & Support

Complete training on the software is included with every machine purchase, and we will setup your initial library with your specific features and doors so you hit the ground running.

You can find KvalCAM's API documentation online at the Kval Docs site. We are constantly improving our documentation and the topics covered. The site is accessible from hand-held and desktop devices alike so that it can be referenced from anywhere.

Software Ecosystem

Virtually any programming language that supports HTTP can connect to and control KvalCAM's powerful tools by leveraging the built-in REST API. We also developed the tools below to augment KvalCAM's already impressive feature set, allowing customers to extend its capabilities even further.

Barcode Mapper

Generate and manage your custom barcodes for communicating directly with KvalCAM's API. Automate everything.

Data Bridge

Import and export your KvalCAM door jobs and feature groups with this easy-to-use portable tool. Just launch and go.

Ready to elevate your production?

Contact us to find out how KvalCAM can help take your production to the next level. Want a more direct conversation? Feel free to call us at (800) 553-5825