Overview

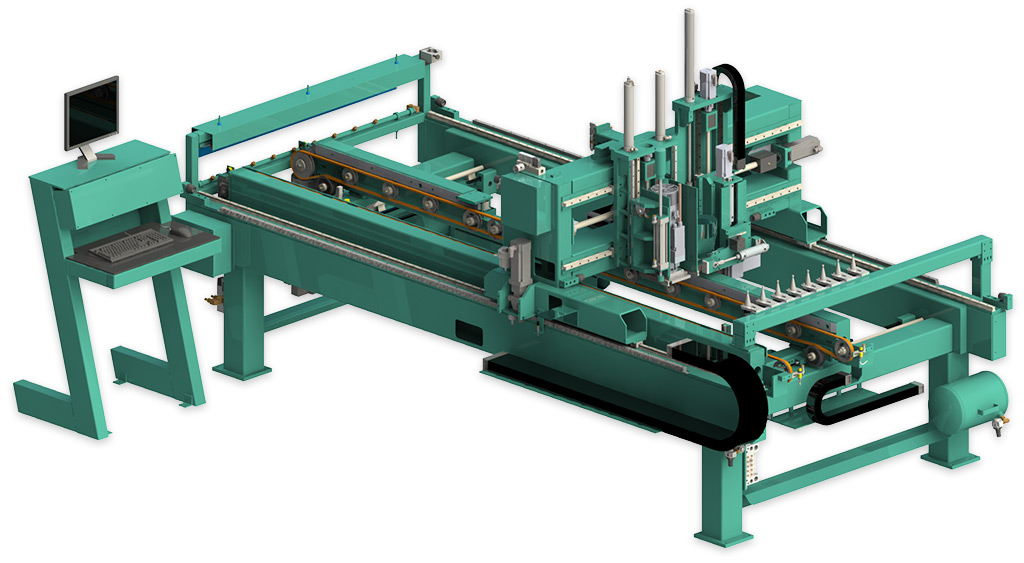

Kval's new DL-NCD Light Cutter Door Machine is equipped with advanced programming to rapidly increase shop productivity and reduce the intensity of labor allowing manufacturers to produce high-quality exterior doors with the exact same process every time.

With the push of a button the DL-NCD automatically feeds, clamps, and measures the door, then runs the CNC machining cycle using our CNC Lock Option and Kval's patented KvalCAM® software.

Industry Leading Quality & Innovation

The DL-NCD utilizes a powerful 10 HP main spindle motor for fast and accurate face work on exterior doors. The door is clamped with the servo motor from the side to prevent door movement. The length of every door is measured to assure exceptional accuracy in lock and light locations, even with slight variances in length from door to door. The DL-NCD will notify the operator if the length is out of specification. A separate encoder measures the door width at the lock location to provide extremely accurate face plate depths and cylinder hole backsets.

Steel and fiberglass foam doors will have the light cut out punched out, while wood door light cut outs will be automatically machined with a relief cut to prevent tear out.

The DL-NCD has an automatic tool changing system with 8 tool slots. The customer can utilize tools for steel, fiberglass, or wood doors. Each tool has individual settings for RPMs and feed rates that are controlled by the customer. Each door file is specified by material type and the proper tool configurations are automatically used.

Key Features

The DL-NCD is equipped with the highest quality components.

10 HP Main Machining Head with HSD tool changer, upgradeable to 13.5 HP.

8 Tool Locations that can be utilized for steel, fiberglass, or wood doors.

Clamps door from sides so door cannot move compared to vacuum systems.

Every door is measured in length to accurately locate the lock and door lights from the top of the door.

Steel Doors and Fiberglass doors can be in the same stack, and KvalCAM will automatically change the tools to the correct door type based on the door file information.

With KvalCAM locks and light opening are easy for customers to program without the knowledge of G-Code. Even ovals and special light patterns can be programmed by the customer.

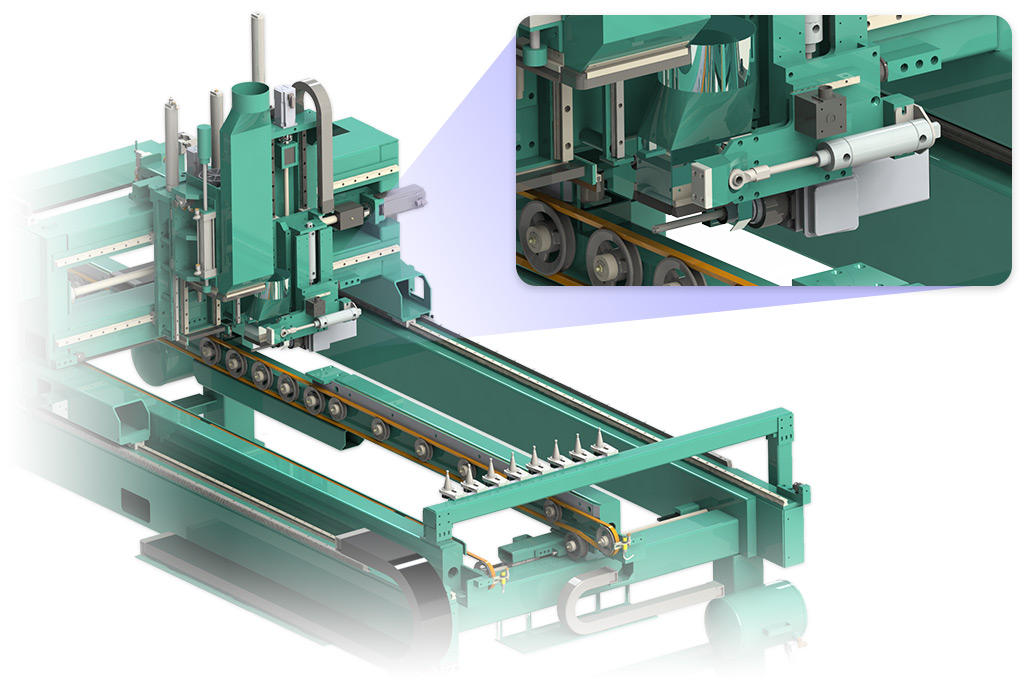

Edge Prep

A 3 HP Lock Edge motor (pictured) can be equipped to machine different size faceplates for both the lock and deadbolt and can even machine mortise or pocket locks.

An encoder measures the door width at the lock location to provide extremely accurate face plate depths and cylinder hole backsets.

KvalCAM® Will Supercharge Your Production

Our expert Software Engineers developed the KvalCAM platform to empower our customers to easily create custom templates and doors without knowledge of G-Code or other programming languages.

Massive Library

Saved door features—selected from the pre-built library or your own custom templates—can be quickly loaded to create a complete door job that includes all edge work and lock face holes.

Powerful Templating

Ovals, diamonds, and other special light patterns can be created by the customer with a CAD drawing of the shape and directly importing into our system. Most other manufacturers charge for special G-Code programs that can also delay production when new shapes are required.

Connected Infrastructure

Software can be utilized on office computers and at the DL-NCD machine to connect to the same database, allowing off-line programming, hardware optimization, and library management.

Flexible Integration

KvalCAM includes a built-in REST API that can be leveraged to generate template files and perform myriad other tasks, e.g. incorporating a barcode system to automate door job creation.