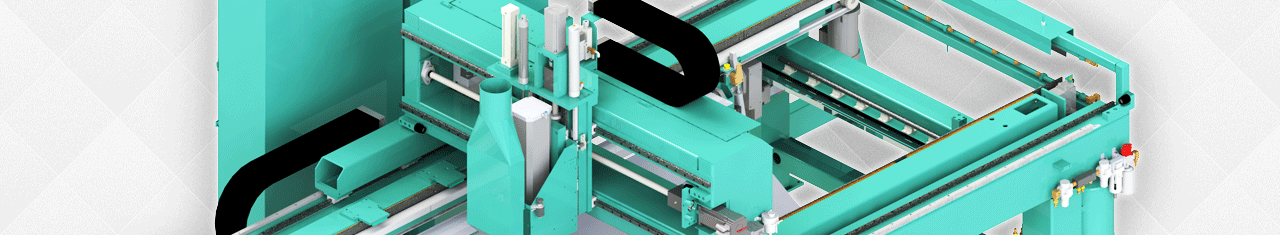

DL-NCX Advanced Door Lite Cutouts

The DL-NCX Numerically-Controlled Door Light Cut-Out Door Machine is a robust architectural door processor with 15HP spindle, auto tool changer and features heavy duty drives and bearing components. An automatic corner squaring system is standard for flush glazed light panels utilizing a squaring mechanism sourced from Successor Industries.

Servo motors, drives, and computer system are by Beckhoff controlled and driven with Kval software produced using C sharp. The software is graphics based, and automatically post processes to gcode so minimal operator training is required. Rectangles and arcs are specified by entering dimensions into template screens, while custom shapes such as ovals can be created directly with industry standard gcode files.

KvalCAM on the DL-NCX allows customers to create square and rectangular template files by simply creating the geometric shape at touch screen or on remote desktop and then saving to library or downloading direct to “queue”. For more difficult shapes, such as ovals, KvalCAM allows operator to import .cad or .dxf files directly which in turn auto-generates the template. The machine will then reference all queued templates to automatically generate the gcode necessary for processing.

All DL-NCD installations require that the integrated PC computer has access to broadband internet for real-time diagnostics and firmware updates. On-board diagnostic programs allow the user to determine the source of operating errors and failures, even after they have occurred.

Computer Controlled

The onboard Kval control software is easy to use and always connected: on-demand support and optimizations can be delivered rapidly

Remote Support

Connect on-line with our techs directly from the on-board computer for issue diagnosis and troubleshooting

Customizable

Kval machines can be customized to fit your company's needs and applicationsAdvanced Door Lite Cutouts