Overview

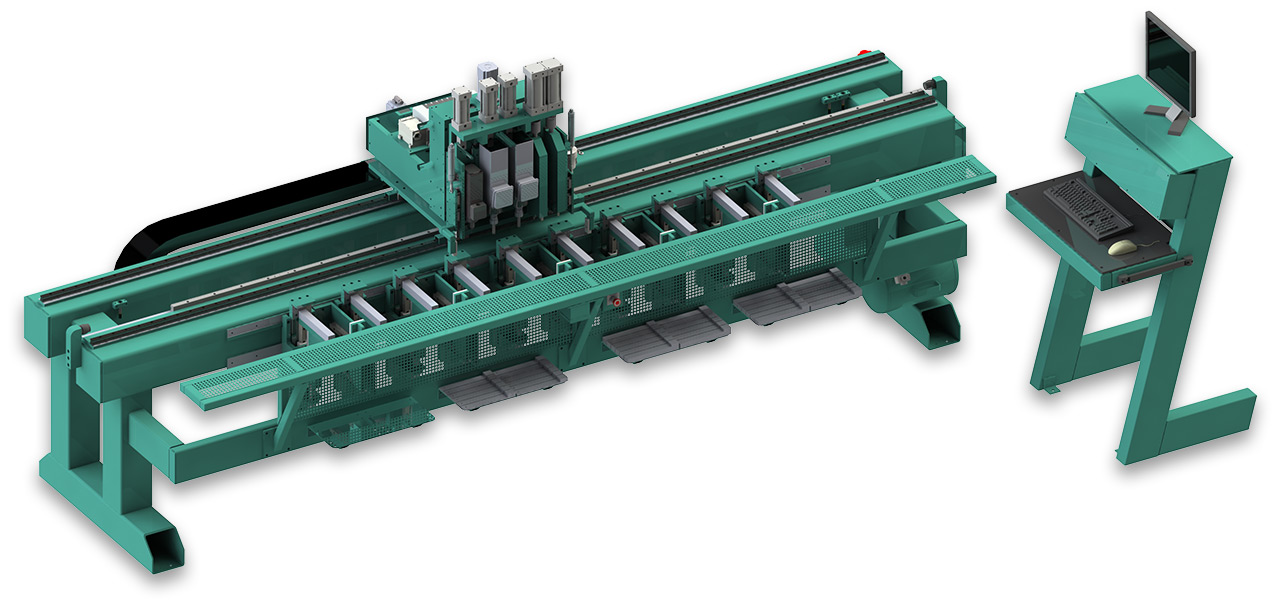

The 965X allows customers to easily program and machine all of their door frame needs with a single compact machine: hinge and strike jambs, headers, mullions, astragals and more.

Powered by our innovative KvalCAM® software, the machine features rapid programming of hinges, T-strikes, 3-point locks, ball catches, dados, angled sill cuts, pilot holes, and cut-to-length on both jamb ends.

Key Features

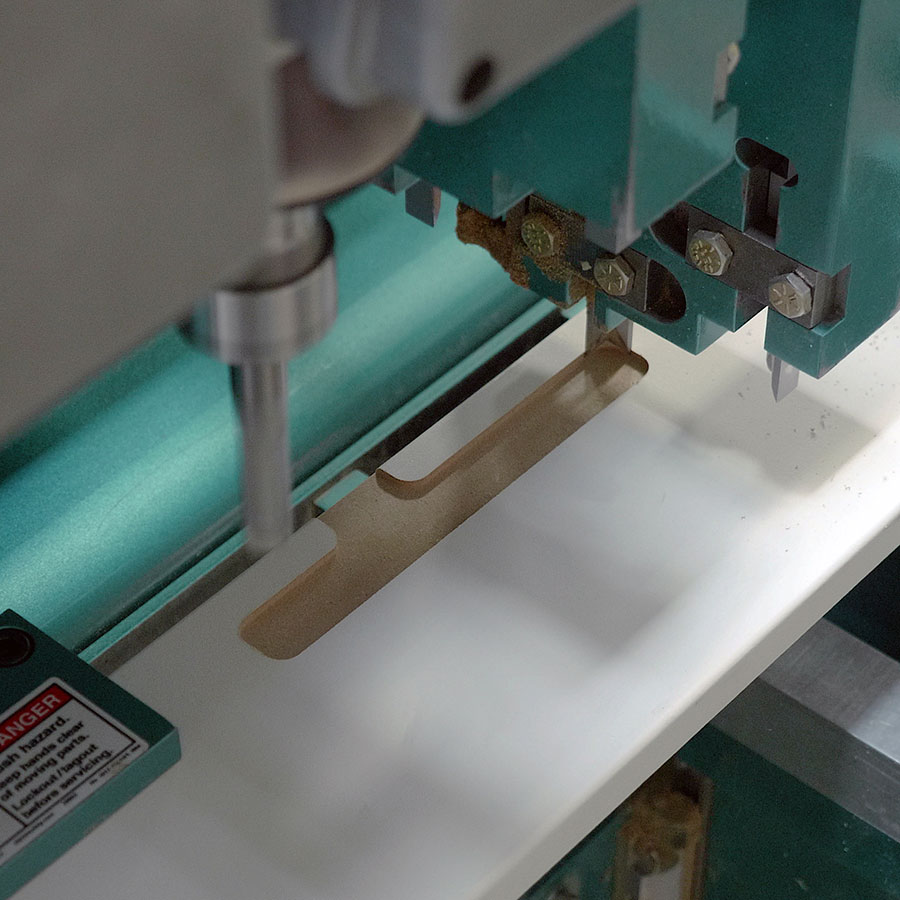

Unique design includes right hand and left hand routers to eliminate chip out.

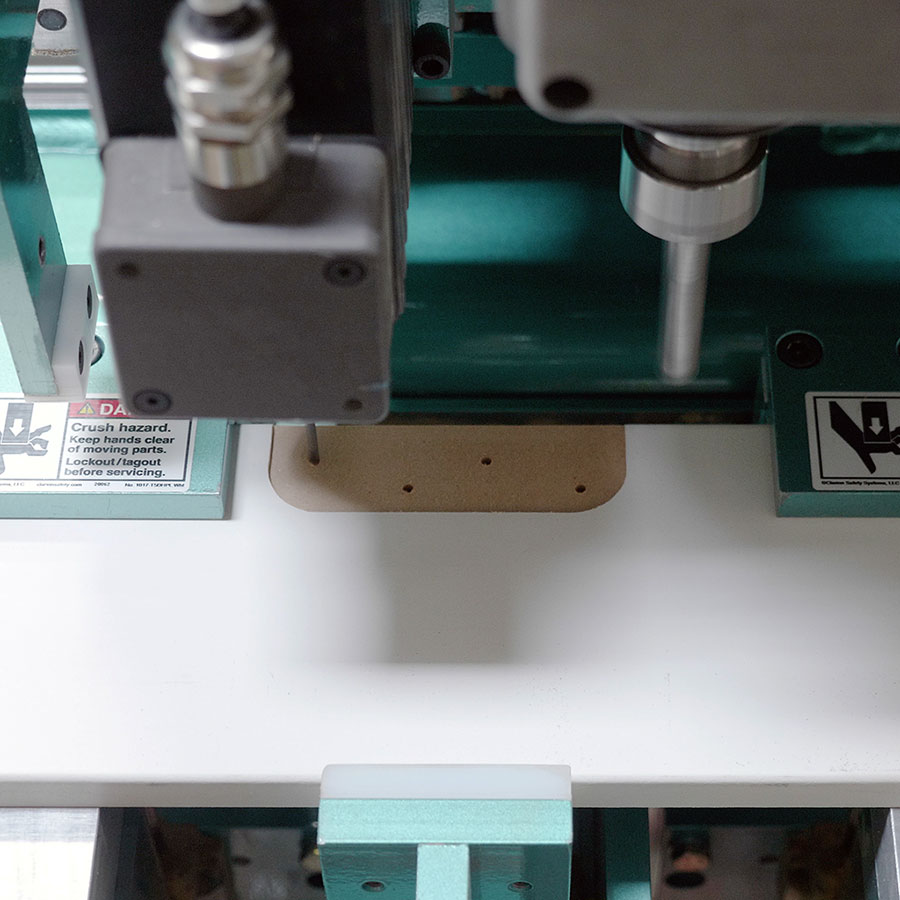

Four 90-degree chisels are used for precise corner squaring on hinges and face plates.

Ten clamping fixtures that clamp upwards without flexing the jamb.

Jamb thickness and material variations are not a concern.

Adaptable fixtures to hold mullions and astragals.

CNC pilot hole programming & Beckhoff™ Controls.

Specifications

- Jamb Max Height (one cycle)

- 101"

- Jamb Max Height (may take two cycles)

- 123"

- Jamb (Mullion) Thickness Max

- 2½"

- Jamb Width

- 1¾" – 9¼"

- Jamb Cut Down Limit

- 101" L, 8½" W, 1⅜" H

- Chisel Depth

- 5⁄16"

The Ultimate Software Platform

The 965X is programmed and controlled by our patented KvalCAM® software that has been in development for over five years. Jamb files are easily created at the controller, offline, or automatically from your data system through its easy-to-use API.

Complex hardware templates including dados, hidden hinges, and angled jamb cuts are easy to create through the intuitive UI.

No G-Code experience is necessary to program new and unique door files. Jobs can be queued for operator or automatic bar-code reader selection, and 3D drawings can be viewed in real time as the door file is created. All machine control, calibration, and tool management is done through KvalCAM’s intuitive UI.