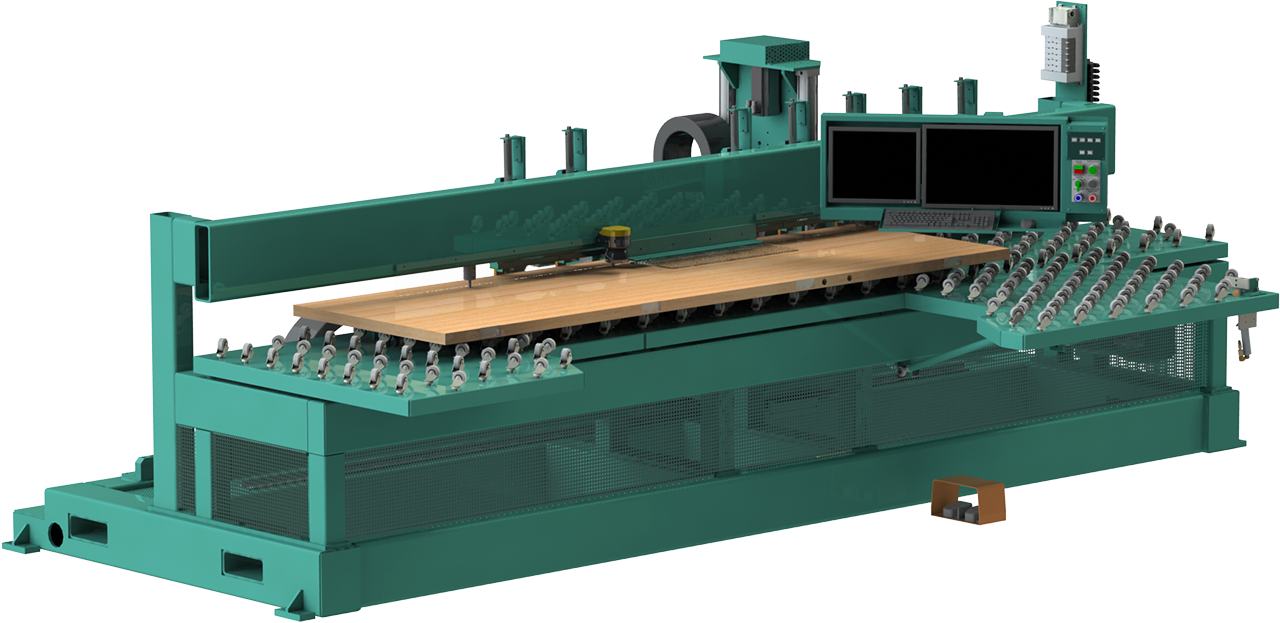

One Machine Does it All

Designed specifically for the Commercial and Architectural Door Distributor; architectural hardware templates including hinges, mortise locks, card locks, exit devices, overhead closers, door bottoms, and flushbolts can be easily programmed and machined without any knowledge of G-Code or other programming languages.

The EFX processes doors up to 4'×9' and 2 ¼" in thickness with a production capacity of 60-100 architectural doors per shift, depending on individual hardware complexity needs; it can complete a door with three 4 ½" squared hinges (including pilot holes) and a commercial cylinder lock in under 3 ½ minutes, door-to-door.

It’s the perfect option for machining the highest quality commercial doors in a small footprint without breaking the bank!

Hardware on the Cutting Edge

Speed

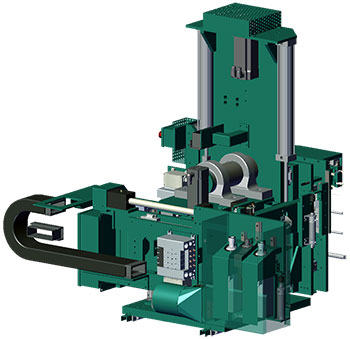

Seven different router motors for face and edge machining allow the EFX to complete all door templates without wasting machine time for tool changes. A 12 HP hogging router provides fast, clean, and accurate machining of mortise pockets and overhead closers.

Quality

Corner chisels and a pre-drill motor for pilot holes guarantee that hinges and faceplates are perfectly completed without additional manual labor. RH and LH routers combine to eliminate chip out in hinges and open lip hardware. The EFX provides the most accurate and clean cuts every time.

Accuracy

Corner chisels and a pre-drill motor for pilot holes guarantee that hinges and faceplates are perfectly completed without additional manual labor. RH and LH routers combine to eliminate chip out in hinges and open lip hardware. The EFX provides the most accurate and clean cuts every time.

- Each chisel has its own easy and accurate calibration.

- Servo depth also individually calibrated – no drag marks and clean corners every time.

- Efficient and clean machining of hinges and face plates.

- Eliminates chip out with relief cuts and machines ¼” radius face plates.

- Precise holes over ¾" in diameter.

- Function hole ⅜" to ⅝" in diameter.

A Higher Standard

The EFX's standard configuration is detailed below, but tooling size and diameter can be controlled by the customer. KvalCAM® automatically writes the machining program with the tools entered when a door is loaded, and tool changes and calibration are done easily without assistance.

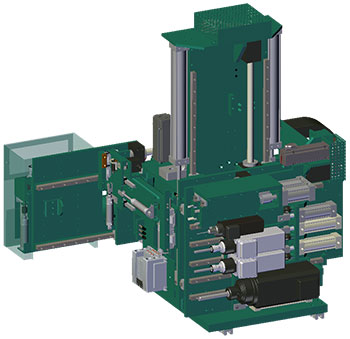

- Counter and standard rotating high frequency routers for edge machining provide the highest quality machining for hinges and open lip hardware without chip out.

- A 12 HP hogging router provides fast, clean, and accurate machining of mortise pockets and overhead closers.

- Three face routers efficiently machine the lock holes from underneath the caster table bed, including small through holes on cylinder locks, mortise function holes, and complex exit devices. The software will notify the operator if the door needs to be flipped for holes that are partially through the top face.

- Corner chisels and a predrill motor for pilot holes so hinges and faceplates are completed without additional manual labor.

- Rack and Pinion x-axis for fast, solid, and precise tower movements.

KvalCAM® Will Supercharge Your Production

Our expert Software Engineers developed the KvalCAM platform to empower our customers to easily create custom templates and doors without knowledge of G-Code or other programming languages. Hardware templates can be created, saved, and modified by simply defining the shapes and locations of lock holes, hinges, faceplates, and other hardware.

Massive Library

Saved door features—selected from the pre-built library or your own custom templates—can be quickly loaded to create a complete door job that includes all edge work and lock face holes.

Powerful Templating

The G-Code that controls the machine's hardware is automatically generated by KvalCAM based on the tools available in the line: our software can control multiple machines used in combination, e.g. the DL-NCD Door Light Cutter can be combined with the EFX to increase production and utilize the KvalCAM templates.

Connected Infrastructure

Software can be utilized on office computers and at the EFX machine to connect to the same database, allowing off-line programming, hardware optimization, and library management.

Flexible Integration

KvalCAM includes a built-in REST API that can be leveraged to generate template files and perform myriad other tasks, e.g. incorporating a barcode system to automate door job creation.