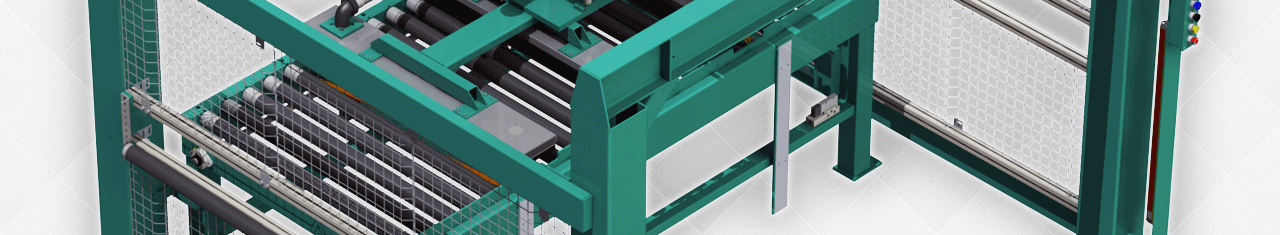

ON-3 Automatic Feeder/Stacker

The ON-3 Door Machine in Feeder configuration automatically lifts individual doors from stacks up to 7’ high and places them onto a powered roll table where they are fed to the next machine either manually with a “Call Door” switch, or automatically when the next machine in the line is ready. Cycle time is approximately 20 seconds.

In Feeder configuration the ON-3 accommodates doors up to 4’ × 8’. The door is clamped on the top and bottom rails by air cylinders. The clamp system will lift doors that vary in height from 6’6” to 8’0” with no need for adjustment. Doors can be between 1⅜” and 1¾” thick with a maximum weight of 175 lbs. Wire guards are attached to the machine’s frame on three sides with a slot opening to allow the door to be fed to the next machine.

The standard ON-3 Feeder is designed to work with door stacks centered in width on top of each other. If a fixed edge stile is required, and doors will be more than 3’0” wide, Option AD is required with Joulin vacuum lifting system.

The ON-3 in Stacker configuration lifts flush or panel doors off of a roll table and places them on a door stack. Lifting capacity is 175 lbs. Door is received from the machinery line, lifted and held by air pressure clamps and cylinders from both ends of the door, or by vacuum cups, then moved automatically on an overhead track system to be lowered onto a stack of doors. Cycle time is 20 seconds.

It will automatically find the level of the door stack during off-feed operation and accommodates stacks up to 84” high with door dimensions up to 4’ × 8’ and 1¾” thick.