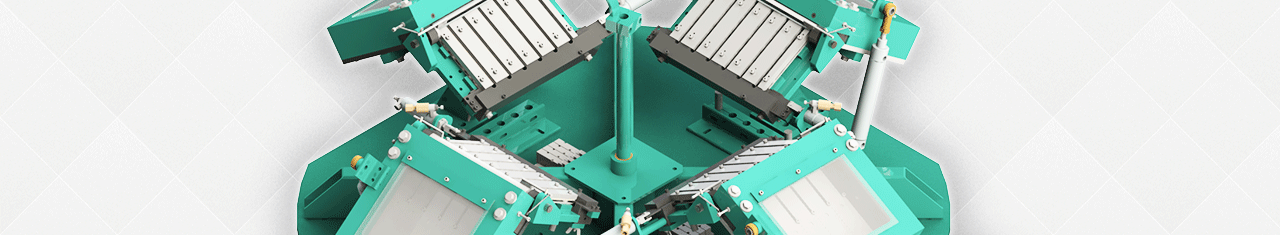

RTS Rotary Hopper

The RTS is our patented companion station for the next generation of pre-hanging equipment; allowing up to four sets of screw colors or sizes to be changed with the press of a button.

This machine reduces changeover time, logistical error by hinge-color batching, and even the risk of operator injury inherent to older and competing designs.

How it works

The operator makes the desired screw selection on the easy-to-use touch screen and 1 of 4 hoppers automatically indexes into position, allowing the correct screw to feed to the 6-shooter hinge-applicator. With this revolutionary system screw changes range from 4-8 seconds dependent on the current screw-hopper location in relation to the desired screw-hopper.

Included is custom framework designed to fit in front of either a Kval Door-Loader (ON-3/Handler) or a Kval Door-Framing Machine. For upgrades other custom fittings and alterations may be necessary: get in touch with us with your specific needs for more details.

Computer Controlled

The RTS machines are simple and safe to operate from the touchscreen computer interface, which can either be integrated into the screw-receiving machine or directly onto the RTS frame.

Quick Changeover

Drastically reduces screw changeover time, enabling your production workflow to operate at full speed while keeping your operators safe.