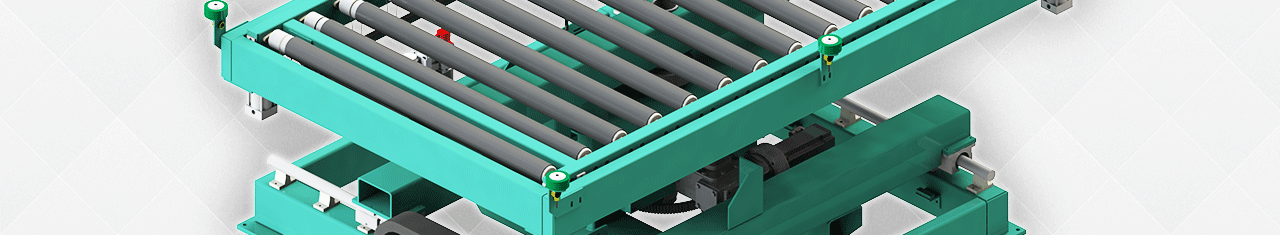

AR-HQ2 Rotate & Transfer Conveyor

The AR-HQ2 rotate and transfer conveyor is designed to receive, correctly orient, and deliver doors to two or three different adjacent conveyors or door frame assembly stations. The receiving stations are oriented surrounding this station at 90 degree intervals.

Non-marking Polyurethane rolls are used to support and feed doors into the surrounding conveyors and machinery. The operator can receive doors with raised mouldings up to 5/8” proud of the door face.

Programming includes an interface with the sending machine, typically a 994-X or Commander-3, to communicate incoming door handedness and width parameters. The width distance between the feed belts is automatically adjusted to match the sending machine, and a servo controlled motor is used to center the pivot point between the belts on the incoming door. A second servo controlled motor is used to rotate the table 90-degrees in either direction (or even 180-degrees if required) prior to out-feed to the next station. The rotate and center pivot functions allow doors to always transfer with sill end leading to any of the three potential destinations, and it can be programmed to deliver doors centered on the door width, or aligned with hinge side door stile.